The essential 5 parts of a Robot that you need to know about

Did you know that robots are made up of 5 very important parts which make their operation possible?

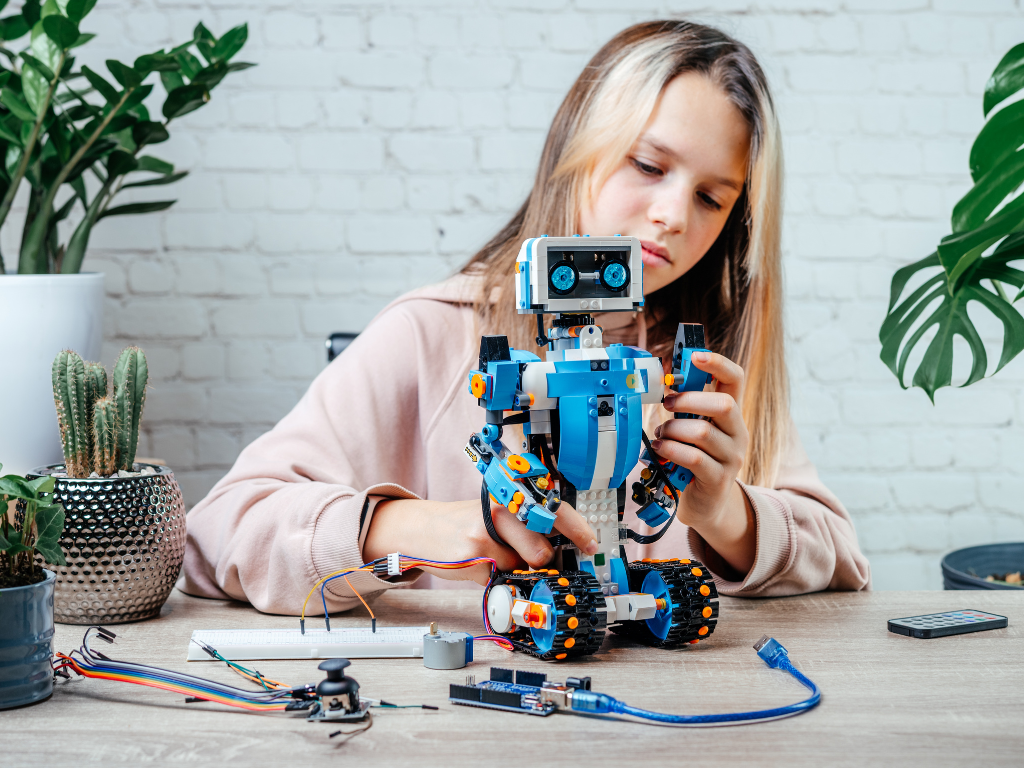

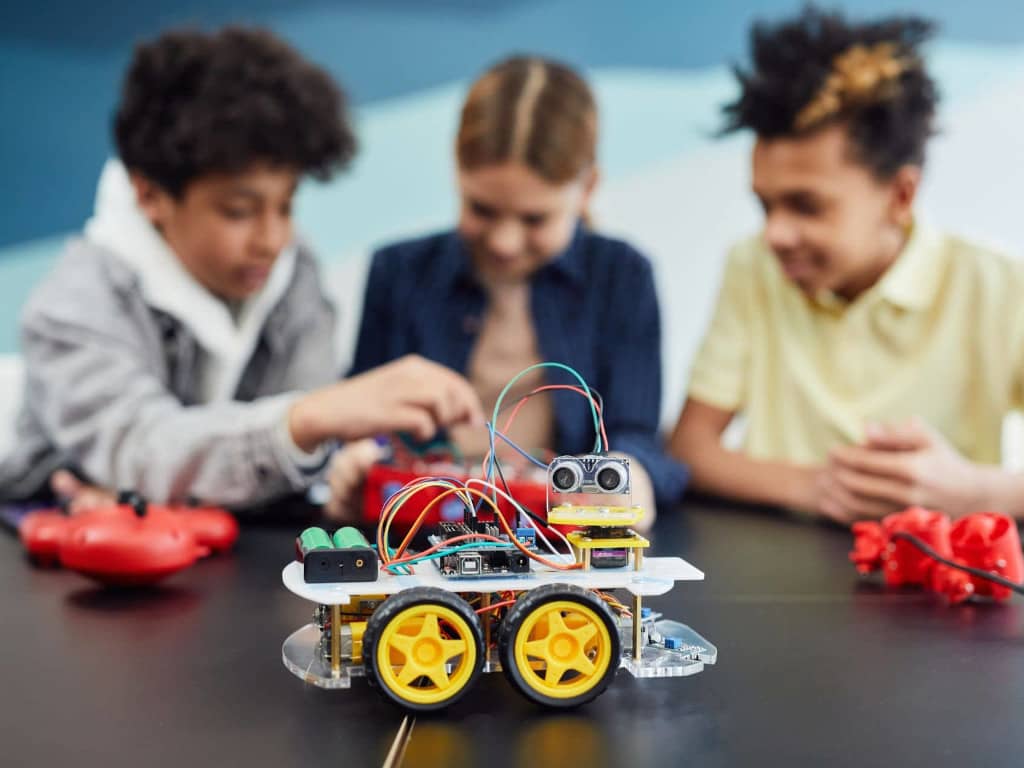

Robots can perform a wide variety of activities which allow them to collect information for processing in order to make decisions, an example is the robotic arm. There are also robots that are designed to function as vehicles (automobiles, airplanes, submarines) or tools (vacuum cleaners, cell phones, computers, home or office assistants). The purpose is to help humans in their various tasks in the home, medicine and scientific research.

But what are these 5 essential parts, let’s get to know them one by one:

1. Joints. Equivalent to the limbs of the human body, in the robot these joints work thanks to electrical connections and the electric, hydraulic or mechanical motor.

2. Effector. It performs the movement or displacement activities and is controlled by the robot’s computer. The effector can be a tool such as a hammer, polisher, screwdriver, tweezers, etc., or cutting and suturing tools to perform surgeries in a hospital or clinic. We can also name the wheels and propellers in robotic airplanes.

3. Motor. This can be AC (for high torque level) or DC (high speed), DC motors are not very powerful so they require gears. There are several types of motors that we will explain below:

– The servomotor, AC or DC type that are combined with a device or position sensor and a control circuit, this motor is a rotating solenoid that gives precision control and angular position.

–The stepper motor (stepper motors in English), is an electric DC motor that divides a complete rotational movement in an equal number of sequential steps, this makes it does not require a position sensor that feeds back to fulfill its task, they are very accurate in positioning and / or speed control.

-Linear actuators that create motion in a straight line, convert the energy generated by an electric motor into torque to move a mechanism. The control system can be mechanical, electrical or computer software. If the task requires a greater amount of force then the moving parts on the robot will use pneumatic or hydraulic parts.

4. Control system. Formed by software and hardware, which directs and controls the motion functions of the robot in order to execute the tasks assigned to it. The robots in this aspect, can be pre-programmed or autonomous. Pre-programmed robots perform repetitive tasks over and over again. Autonomous robots are able to read and respond to changes in the environment in which they operate by means of sensors.

5. Sensors. They are measuring instruments for values of position, velocity, force, torque, proximity, temperature, weight, etc. The data collected by the sensors feed the control system of the robot. Among the variety of sensors that a robot may have, we have: cameras for visual perception, microphones that allow recording sounds, lasers that build 3D maps, high frequency sound devices, accelerometers and magnetometers that allow the robot to determine its own movement with respect to the force of gravity and the earth’s magnetic field, pressure pads, infrared sensors, GPS, potentiometers, gyroscopes, thermal sensors, humidity sensors, gas sensors, etc.

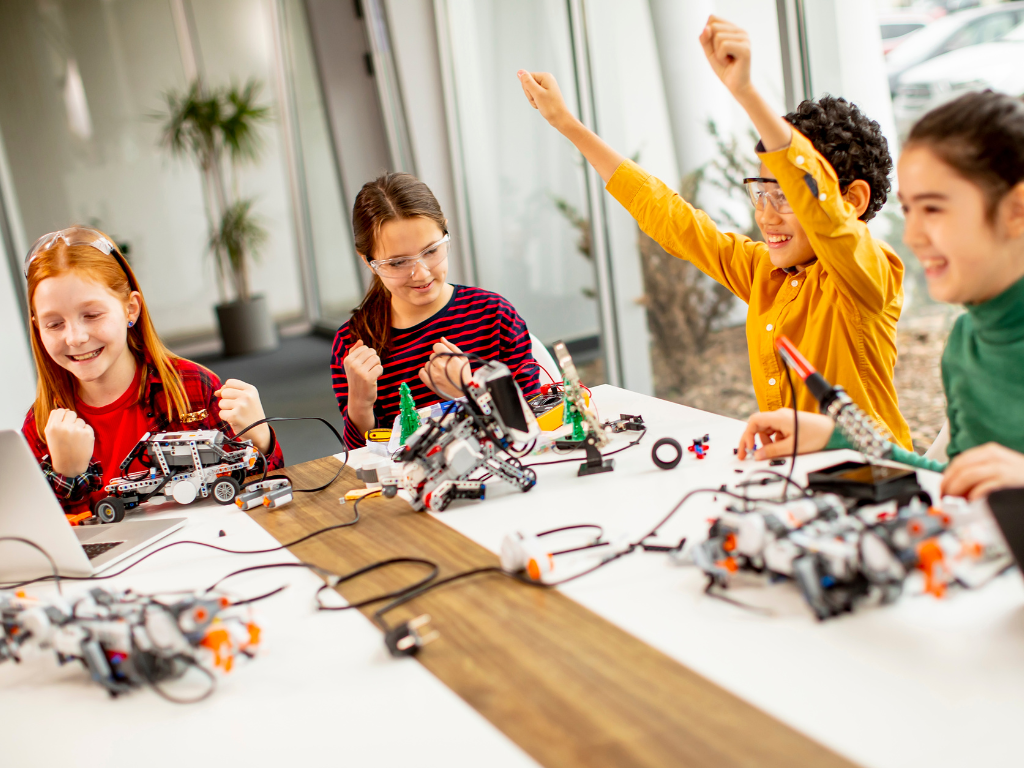

The world of robotics is one where many things are possible, if you are interested in robotics and want to learn how to build one, I invite you to sign up for the Ecorobotik competitions, you will not only learn how to build one with recycled parts, you will also meet more people who will share your passion for technology. In the following publications I will talk about the different types of sensors and the functions of each one of them.

Do you find this topic interesting? Share it on your social networks and don’t forget to follow us on Instagram and Facebook.